Glass Fiber Reinforced Concrete (GFRC), also known as Glassfibre Reinforced Concrete (GRC) in some regions, is a type of concrete that is reinforced with glass fibers to enhance its physical properties. GFRC is a composite material consisting of:

- Cement: The primary binding agent.

- Fine Aggregates: Typically sand.

- Water: Essential for hydration and mixing.

- Glass Fibers: The reinforcing component that provides tensile strength and durability.

- Chemical Admixtures: Used to improve the properties of the mix, such as workability and setting time.

Key Characteristics of GFRC:

- High Strength: The inclusion of glass fibers significantly increases the tensile strength of the concrete.

- Lightweight: GFRC is much lighter than traditional concrete, making it easier to handle and install.

- Durability: Resistant to weathering, corrosion, and environmental conditions, ensuring a long lifespan.

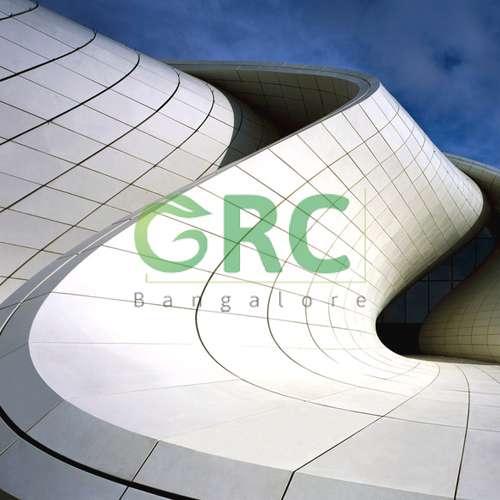

- Versatility: Can be molded into complex shapes and intricate designs, making it ideal for architectural and decorative applications.

- Fire Resistance: Inherent fire-resistant properties, adding to the safety of the structures where it is used.

Applications of GFRC:

- Architectural Facades: Used for creating decorative and structural facades due to its ability to mimic various textures and finishes.

- Cladding Panels: Lightweight panels that provide insulation and aesthetic appeal.

- Decorative Elements: Used for making intricate designs such as jalis (perforated screens), cornices, and moldings.

- Structural Components: Columns, pillars, and beams that benefit from the added tensile strength of GFRC.

- Planters and Landscaping: Durable and weather-resistant planters and landscaping features.

- Noise Barriers: Effective in reducing noise pollution in urban areas.

- Fountains and Sculptures: Ideal for outdoor decorative features due to its durability and ease of molding.

Benefits of GFRC:

- Enhanced Strength: The glass fibers significantly improve the tensile and flexural strength of the concrete.

- Weight Reduction: Being lighter than traditional concrete, it reduces the load on structures and simplifies installation.

- Durability: Offers excellent resistance to environmental factors, reducing maintenance costs.

- Design Flexibility: Can be cast into any shape, allowing for innovative and unique architectural designs.

- Sustainability: Can be produced with low embodied energy and is recyclable, contributing to sustainable building practices.

Manufacturing Process:

- Mixing: The components (cement, fine aggregates, water, glass fibers, and admixtures) are mixed to form a homogenous slurry.

- Molding: The mixture is poured into molds to create the desired shapes and designs.

- Curing: The molded elements are cured to achieve the required strength and durability.

- Finishing: The cured products are finished as per the design specifications, which may include painting, staining, or adding textures.

At GRC Bangalore, we specialize in producing high-quality GFRC products that cater to the diverse needs of modern construction and architectural design. Our products are manufactured using state-of-the-art technology and the finest materials to ensure the best performance and aesthetic appeal.

Very good https://is.gd/tpjNyL